-

Seamless Alloy Steel Pipe

-

Stainless Steel Seamless Pipe

-

Seamless Carbon Steel Pipe

-

Stainless Steel Pipe

-

SS Welded Tube

-

Stainless Steel Sheet Plate

-

Stainless Steel Coil Strip

-

Stainless Steel Bars

-

Stainless Steel Wire Rod

-

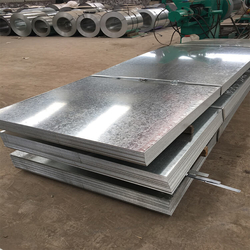

Carbon Steel Plate

-

Carbon Steel Coil

-

Carbon Steel Tubes

-

Carbon Steel Bar

-

Carbon Steel Wire

-

Alloy Steel Sheet

-

Alloy Steel Coil

-

Alloy Steel Bar

-

Alloy Steel Wire

-

EduardoThe coil was packaged very well and shipped fast.The product fits the descripton. Thinking about purchasing again.Really a great product. I have tried other products and this by far is the best money I have spent.

EduardoThe coil was packaged very well and shipped fast.The product fits the descripton. Thinking about purchasing again.Really a great product. I have tried other products and this by far is the best money I have spent. -

DavidFirst time we import a big project from China, excellent for service And really professionnal. My goods have been received, the products are not damaged at all.The quality and workmanship are very good, the materials are also very good, I am very satisfied. recommand them!

DavidFirst time we import a big project from China, excellent for service And really professionnal. My goods have been received, the products are not damaged at all.The quality and workmanship are very good, the materials are also very good, I am very satisfied. recommand them! -

HuzeshafiI am very satisfied with this import. The quality is very good and the price is reasonable. The seller is very professional and responsive. I will definitely buy from this seller again.

HuzeshafiI am very satisfied with this import. The quality is very good and the price is reasonable. The seller is very professional and responsive. I will definitely buy from this seller again.

Prime Hot Rolled Alloy Steel Wire Rods SAE 1010 20mm

| Place of Origin | Shandong China |

|---|---|

| Brand Name | TESTE |

| Certification | ISO TUV SGS BIS CE |

| Minimum Order Quantity | 3Tons |

| Price | Negotiate |

| Packaging Details | With iron sheet to pack the steel sheet and pallet .Also make the shipping marks on each bundles. |

| Delivery Time | 5-15days depend on the quantity |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram,OA |

| Supply Ability | 5000Tons Per Months |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | High Carbon Steel Wire Rods | Standard | JIS G3506,ASTM A510 |

|---|---|---|---|

| Size | 5.5mm~20mm | Technology | Hot Rolled |

| Surface | Black | Product Name | Carbon Steel Wire |

| High Light | Pipe | ||

| Highlight | prime hot rolled steel wire rods,hot rolled alloy steel wire SAE 1010,hot rolled alloy steel wire 20mm |

||

AISI 1010 carbon steel is a plain carbon steel with 0.10% carbon content. This steel has relatively low strength but it can be quenched and tempered to increase strength.

GRADE

| Steel Wire Rod | Standard | Grade |

| ASTM A510M |

Low Carbon Steel : SAE 1006 SAE 1008 SAE1010 SAE 1012 SAE 1013 SAE 1015 SAE 1016 SAE 1017 SAE 1018 SAE 1020 SAE 1022 SAE 1023 SAE 1025 Medium Carbon Steel : SAE 1030 SAE 1035 SAE 1040 SAE 1045 High Carbon Steel : SAE1050 SAE 1055 SAE 1060 SAE 1065 SAE 1070 SAE 1080 |

|

| DIN EN ISO 16120-2 |

C32D C38D C42D C48D C50D C52D C56D C58D C60D C62D C66D C68D C70D C76D C78D C80D C82D C86D C88D C92D |

|

| JIS G3506 |

SWRH27 SWRH32 SWRH37 SWRH42A SWRH42B SWRH47A SWRH47B SWRH52A SWRH52B SWRH57A SWRH57B SWRH62A SWRH62B SWRH67A SWRH67B SWRH72A SWRH72B SWRH77A SWRH77B SWRH82A SWRH82B |

CHEMICAL COMPOSITION

| Element | C | Mn | P | S |

| SAE 1010 | 0.08~0.13% | 0.30~0.60% | 0.04%Max | 0.05%Max |

| SAE 1040 | 0.18~0.23% | 0.60~1.20% | 0.04%Max | 0.05%Max |

| SAE1060 | 0.55~0.66% | 0.60~0.90% | 0.04%Max | 0.05%Max |

| SAE1065 | 0.60~0.70% | 0.60~0.90% | 0.04%Max | 0.05%Max |

| SAE 1070 | 0.70%Max | 0.75%Max | 0.04%Max | 0.05%Max |

| SAE 1080 | 0.75~0.88% | 0.60~0.90% | 0.04%Max | 0.05%Max |

The machinability of AISI 1010 carbon steel, especially in the cold drawn or cold worked state, is considered as fairly good.

FORMING

AISI 1010 carbon steel has good formability and ductility, and can be easily formed using conventional methods.

WELDING

AISI 1010 carbon steel can be welded using all the conventional welding techniques.

HEAT TREATMENT

AISI 1010 carbon steel is mostly used in the annealed or case hardened condition. However, it can also be heat treated, quenched and tempered but the cost for performing these processes are very high.

FORGING

Forging can be performed on AISI 1010 carbon steel between 1260 and 982°C (2300 and 1800°F).

HOT WORKING

The hot working capacity of AISI 1010 carbon steel is between the ranges of 482 to 93°C (900 to 200°F).