-

Seamless Alloy Steel Pipe

-

Stainless Steel Seamless Pipe

-

Seamless Carbon Steel Pipe

-

Stainless Steel Pipe

-

SS Welded Tube

-

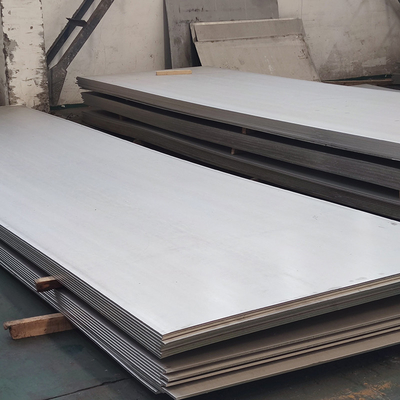

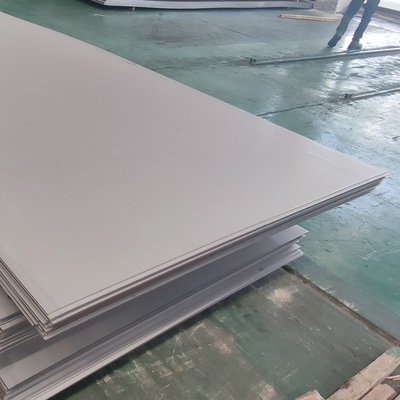

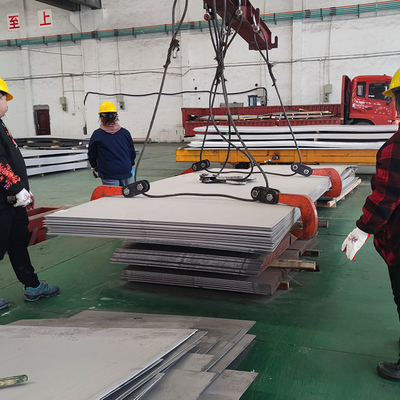

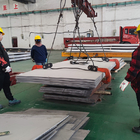

Stainless Steel Sheet Plate

-

Stainless Steel Coil Strip

-

Stainless Steel Bars

-

Stainless Steel Wire Rod

-

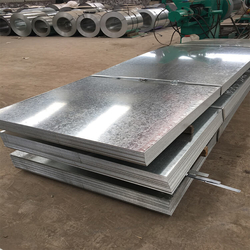

Carbon Steel Plate

-

Carbon Steel Coil

-

Carbon Steel Tubes

-

Carbon Steel Bar

-

Carbon Steel Wire

-

Alloy Steel Sheet

-

Alloy Steel Coil

-

Alloy Steel Bar

-

Alloy Steel Wire

-

EduardoThe coil was packaged very well and shipped fast.The product fits the descripton. Thinking about purchasing again.Really a great product. I have tried other products and this by far is the best money I have spent.

EduardoThe coil was packaged very well and shipped fast.The product fits the descripton. Thinking about purchasing again.Really a great product. I have tried other products and this by far is the best money I have spent. -

DavidFirst time we import a big project from China, excellent for service And really professionnal. My goods have been received, the products are not damaged at all.The quality and workmanship are very good, the materials are also very good, I am very satisfied. recommand them!

DavidFirst time we import a big project from China, excellent for service And really professionnal. My goods have been received, the products are not damaged at all.The quality and workmanship are very good, the materials are also very good, I am very satisfied. recommand them! -

HuzeshafiI am very satisfied with this import. The quality is very good and the price is reasonable. The seller is very professional and responsive. I will definitely buy from this seller again.

HuzeshafiI am very satisfied with this import. The quality is very good and the price is reasonable. The seller is very professional and responsive. I will definitely buy from this seller again.

Bendable Cold Rolled Stainless Steel Sheet Plate 904l 420 405 4mm 3mm

| Place of Origin | Shandong China |

|---|---|

| Brand Name | TESTE |

| Certification | ISO TUV SGS BIS CE |

| Minimum Order Quantity | 3Tons |

| Price | Negotiate |

| Packaging Details | With iron sheet to pack the steel sheet and pallet .Also make the shipping marks on each bundles. |

| Delivery Time | 5-15days depend on the quantity |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram,OA |

| Supply Ability | 5000Tons Per Months |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Stainless Steel Sheet | Type | Cold Rolled,Hot Rolled |

|---|---|---|---|

| Surface | No.1,2D,2B,BA,No.4,8k,Tempered | Thickness | 0.4mm~6mm |

| Product Name | Stainless Steel Sheet Plate | High Light | . |

| High Light | Pipe | Name | Pipe |

| Highlight | 420 stainless steel plate 1200 x 600,stainless steel 904l plates 1200 x 600,stainless steel 4mm plate 1200 x 600 |

||

Grade 316Ti Stainless Steel Sheet

316Ti (1.4571) STAINLESS STEEL

316Ti (UNS S31635) is a titanium stabilised version of 316 molybdenum-bearing austenitic stainless steel.

The 316 alloys are more resistant to general corrosion and pitting/crevice corrosion than the conventional chromium-nickel austenitic stainless steels such as 304. They also offer higher creep, stress-rupture and tensile strength at elevated temperature. High carbon Alloy 316 stainless steel can be susceptible to sensitisation, the formation of grain boundary chromium carbides at temperatures between approximately 900 and 1500°F (425 to 815°C) which can result in intergranular corrosion. Resistance to sensitisation is achieved in Alloy 316Ti with titanium additions to stabilise the structure against chromium carbide precipitation, which is the source of sensitisation. This stabilisation is achieved by an intermediate temperature heat treatment, during which the titanium reacts with carbon to form titanium carbides. This significantly reduces susceptibility to sensitisation in service by limiting the formation of chromium carbides. Thus, the alloy can be used for extended periods at elevated temperatures without compromising its corrosion resistance. 316Ti has equvilent corrosion resistance to sensitisation as the low carbon version 316L.

CHEMICAL COMPOSITION

| Element | C | Mn | Si | P | S | Cr | Ni | N | Ti |

| 316 | 0.07% | 2.0% | 1.00% | 0.045% | 0.03% | 16.5~18.5% | 10.0~13.0% | 0.11% | - |

| 316L | 0.03% | 2.0% | 1.00% | 0.045% | 0.02% | 16.5~18.5% | 10.0~13.0% | 0.11% | - |

| 316LN | 0.03% | 2.0% | 1.00% | 0.045% | 0.015% | 16.5~18.5% | 10.0~12.5% | 0.12~0.22% | - |

| 316Ti | 0.08% | 2.0% | 0.75% | 0.045% | 0.03% | 16.0~18.0% | 10.0~14.0% | 0.10% | 5x%(C+N)~0.70% |

MECHANICAL PROPERTIES

| Grade |

Tensile Strength (MPa) |

Yield Strength (MPa)Min

|

Density (g/cm3) |

Brinell (HB)Max |

| 316 | 500~700 | 200 | 8 | 215 |

| 316L | 520~680 | 220 | 8 | 215 |

| 316LN | 580~780 | 205 | 8 | 220 |

| 316Ti | 515Min | 205 | 8 | 209 |

316Ti COMMON APPLICATIONS

- Equipment that resists sulfuric acid, phosphoric acid, acetic acid, and acetic acid;

- Petrochemical;

- Mechanical and electrical hardware;

- Shipyard;

- Power plant;

- Others