-

Seamless Alloy Steel Pipe

-

Stainless Steel Seamless Pipe

-

Seamless Carbon Steel Pipe

-

Stainless Steel Pipe

-

SS Welded Tube

-

Stainless Steel Sheet Plate

-

Stainless Steel Coil Strip

-

Stainless Steel Bars

-

Stainless Steel Wire Rod

-

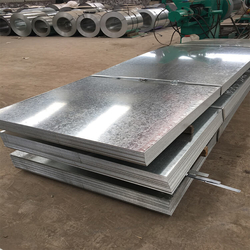

Carbon Steel Plate

-

Carbon Steel Coil

-

Carbon Steel Tubes

-

Carbon Steel Bar

-

Carbon Steel Wire

-

Alloy Steel Sheet

-

Alloy Steel Coil

-

Alloy Steel Bar

-

Alloy Steel Wire

-

EduardoThe coil was packaged very well and shipped fast.The product fits the descripton. Thinking about purchasing again.Really a great product. I have tried other products and this by far is the best money I have spent.

EduardoThe coil was packaged very well and shipped fast.The product fits the descripton. Thinking about purchasing again.Really a great product. I have tried other products and this by far is the best money I have spent. -

DavidFirst time we import a big project from China, excellent for service And really professionnal. My goods have been received, the products are not damaged at all.The quality and workmanship are very good, the materials are also very good, I am very satisfied. recommand them!

DavidFirst time we import a big project from China, excellent for service And really professionnal. My goods have been received, the products are not damaged at all.The quality and workmanship are very good, the materials are also very good, I am very satisfied. recommand them! -

HuzeshafiI am very satisfied with this import. The quality is very good and the price is reasonable. The seller is very professional and responsive. I will definitely buy from this seller again.

HuzeshafiI am very satisfied with this import. The quality is very good and the price is reasonable. The seller is very professional and responsive. I will definitely buy from this seller again.

3“ 304 321 410 439 Welded And Drawn Stainless Steel Tubing Europe Standard

| Place of Origin | Shandong China |

|---|---|

| Brand Name | TESTE |

| Certification | ISO TUV SGS BIS CE |

| Minimum Order Quantity | 3Tons |

| Price | Negotiate |

| Packaging Details | With iron sheet to pack the steel sheet and pallet .Also make the shipping marks on each bundles. |

| Delivery Time | 5-15days depend on the quantity |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram,OA |

| Supply Ability | 5000Tons Per Months |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Stainless Steel Round Pipe | Technique | Cold Rolled,Hot Rolled |

|---|---|---|---|

| Type | Welded Pipe(ERW) | Surface | No.1,2D,2B,BA,No.4,8k,Tempered |

| Highlight | 3 304 stainless steel tubing,321 stainless steel tubing,410 stainless steel tubing |

||

304(1.4301)/304L(1.4307)/304H(1.4948) SEAMLESS&WELDED PIPE

Stainless Steel Grade 304 is the standard 18/8 (18% chrome, 8% nickel) austenitic stainless steel. It is a non-magnetic alloy in the annealed condition, however, becomes magnetic as it is cold worked. It is the most ordinarily utilized of all stainless grades. T304 can be effortlessly welded and is the preferred for many deep drawn, spun or formed parts due to its high ductility.

Stainless Steel Grade 304L has oxidation resistance to a maximum temperature of 1650°F (899°C) continuous without considerable scaling. The maximum temperature for intermittent presentation is 1500°F (816°C). Since 304L is an additional low-carbon variety of 304 it can frequently be utilized in the “as-welded” condition (without annealing), even in severe corrosive conditions, except for applications indicating stress relief. 304L has good welding qualities and can be welded by all standard strategy; however, consideration should be paid to maintain a strategic distance from weld “hot cracking”. To relieve stress during severe forming or spinning welding may be followed by annealing.

Stainless Steel Grade 304H includes a high carbon content making the steel more suitable for utilization in applications where high temperatures are available. The benefit of this grade is that it is an austenitic chromium-nickel steel alloy as well as the greater carbon content distribute to increased tensile and yield strength. The material is recommended for utilizing in ASME pressure vessels in working service above 525° C because of the grade's heat resistant properties.

STOCKING PROGRAM

- Size Range : 1/4″ ~ 36″ NPS (Larger sizes available upon request)

- Schedules : 10, 10s, 40, 40s, 80, 80s, 120, 160 (Custom wall thicknesses available upon request)

- Stainless Steel Grades : 304, 304L, 316, 316L, 316L, 317L, 321 , 347

- Special Alloys : 2205, 254SMo, Monel, Inconel

- Chrome Moly : P5, P9, P11, P22, P91

- Standards : ASTM / ASME

CHEMICAL COMPOSITION

| Element | C | Mn | Si | P | S | Cr | Ni | N | Fe |

| 304 | 0.07% | 2.0% | 0.75% | 0.045% | 0.03% | 17.5~19.5% | 8.0~10.5% | 0.10% | Remainder |

| 304L | 0.03% | 2.0% | 0.75% | 0.045% | 0.03% | 17.5~19.5% | 8.0~12.0% | 0.10% | Remainder |

| 304H | 0.04~0.10% | 2.0% | 0.75% | 0.045% | 0.03% | 18.0~20.0% | 8.0~10.5% | - | Remainder |

MECHANICAL PROPERTIES

| Grade |

Tensile Strength (MPa) Min

|

Yield Strength 0.2% Proof (MPa) Min

|

Elongation (%in 50mm) Min |

Hardness | |

|

Rockwell B (HR B) Max |

Brinell (HB) Max |

||||

| 304 | 515 | 205 | 40 | 92 | 201 |

| 304L | 485 | 170 | 40 | 92 | 201 |

| 304H | 515 | 205 | 40 | 92 | 201 |

ADVANTAGES OF WELDED

- Welded pipes are typically more cost effective than their seamless equivalents.

- Welded pipes are usually more readily available than seamless. The longer lead time required for seamless pipes can not only make timing problematic, but it also allows more time for the price of the materials to fluctuate.

- The wall thickness of welded pipes is generally more consistent than that of seamless pipes.

- The internal surface of welded tubes can be checked before manufacturing, which isn’t possible with seamless.

ADVANTAGES OF WELDED

- The main perceived advantage of seamless pipes is that they don’t have a weld seam.

- Seamless pipes provide peace of mind. Although there should be no issues with the seams of welded pipes supplied by reputable manufacturers, seamless pipes prevent any possibility of a weak seam.

- Seamless pipes have better ovality or roundness, than welded pipes.